Nonwoven fabric (English name: Non Woven Fabric or Nonwoven cloth), also known as non-woven fabric, is composed of directional or random fibers, nonwoven fabric is not woven, but with a lot of needles with barbed wire fibers entangled together, or so that some of their parts adhere together and become a fabric.

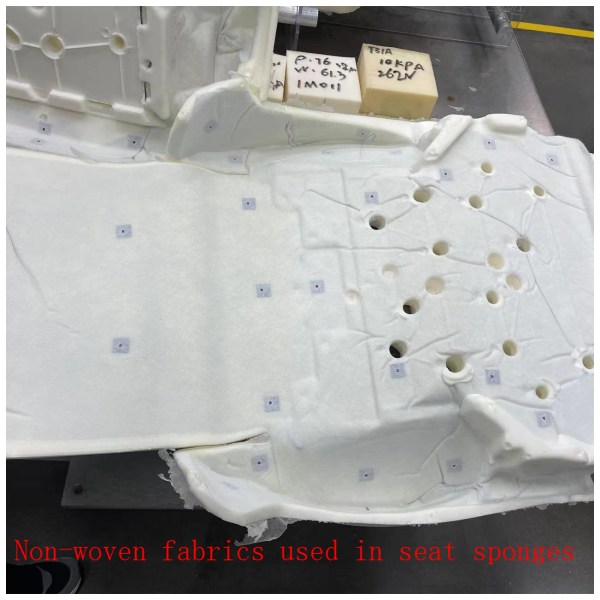

Nonwoven fabric is the standard equipment on the seat, no matter it is used on the back of the foam sponge or between the foam and the skeleton when the seat is assembled, the main purpose is to be used for the sound deadening between the foam and the skeleton of the seat. Because the foam sponge surface due to the existence of bubble holes, the surface is relatively rough, and friction with other objects is easy to produce “squeaking” sound, you need to use this method to avoid this kind of noise.

Characteristics Of Non-woven Fabric

- Soft and comfortable: made of fine fibers in the form of light-dot hot-melt bonding, it is soft to the touch and can enhance the driving comfort.

- Light weight and high strength: light weight, can reduce the weight of the car, save fuel consumption; high strength, not easy to break.

- Breathable: Porous structure allows air circulation, reducing stuffy heat and odor.

- Sound absorption and noise reduction: absorbs and blocks noise, creating a quiet space.

- Thermal insulation: block heat transfer, regulate the temperature inside the car.

- Good processability: no warp and weft threads, easy to cut, sew and shape to meet a variety of designs.

- Low cost: low production cost, which helps to reduce the cost of the whole vehicle.

- Green and environmentally friendly: most of them are made of biodegradable materials, which are friendly to the environment.

Nonwoven Fabrics Play An Important Role In Car Seats

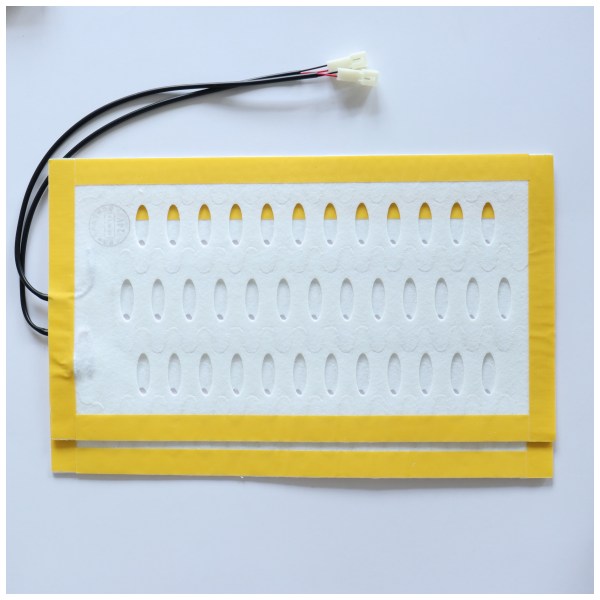

1、Fixed heating wire

In the automotive seat heating system, nonwoven fabric can be used to fix the heating wire, the heating wire will be arranged on the nonwoven fabric, and then tape and other ways to ensure that the heating wire is in a stable position, so that the heat can be uniformly transmitted to the surface of the seat, to provide passengers with a warm ride experience.

2、Support and shaping

Nonwoven fabric can be combined with other materials such as rigid strips to support the face cover of the car seat, ensure that the style lines on the face cover are straight and prevent the face cover from twisting and creasing during the wrapping process, so as to improve the aesthetics and overall quality of the seat.

3、Wrapping filler materials

the seat within the foam and other filler materials to play a wrapping role, so that the filler material to maintain stability, not easy to shift or deformation, but also allows the filler material and the other parts of the seat to better combine to improve the comfort and durability of the seat.

4、Sound insulation and noise reduction

non-woven fabrics have a certain sound-absorbing properties, can be used as soundproofing materials applied to car seats, absorb and block the noise inside the car, reduce the impact of external environmental noise on the car, to create a quieter, more comfortable riding environment for passengers, enhance the driving experience. (As shown in the picture of the car roof covered with nonwoven fabric)

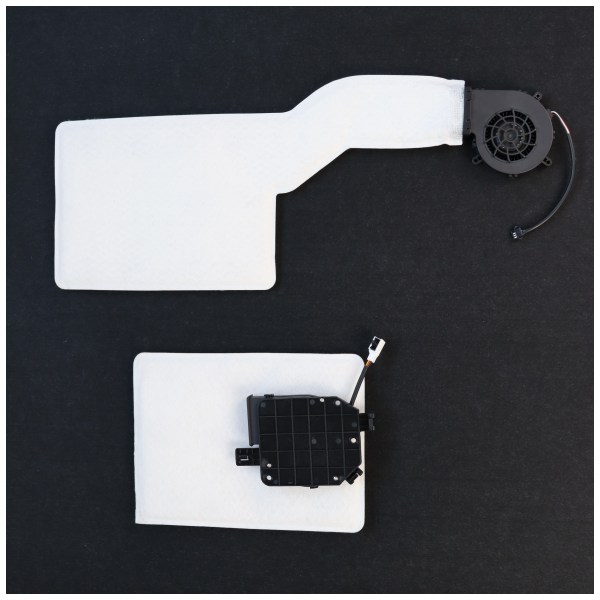

5、Filtration and ventilation

in some car seat design, nonwoven fabric can be used in the ventilation system or filtration device, play a role in filtering the air, removing dust and impurities, to ensure that the air into the seat ventilation system is clean, but also help to maintain the air circulation inside the seat, improve the comfort of the ride.

+86 19906048932

+86 19906048932 sales@luxuryvanseat.com

sales@luxuryvanseat.com | Blog

| Sitemap

| XML

| Privacy Policy

| Blog

| Sitemap

| XML

| Privacy Policy