Foaming is an extremely important process in the design and manufacturing of automobile seats. During the operation, raw materials such as polyether and isocyanate need to be mixed together to promote chemical reactions under certain pressure and temperature conditions, and finally complete the shaping and manufacturing of the seat. In recent years, my country's automobile consumer market has expanded significantly. How to improve the foaming performance of automobile seats and how to strengthen the anti-collapse design of automobile seats have become the focus of many automobile design and manufacturing companies.

1 Types of automobile seat foaming technology

1.1 Composite foaming of cover The emergence of composite foaming of cover is mainly to solve the defects of traditional process. In the traditional mode, the seat cover and the foam body are designed and manufactured separately. After the foam body is cured, the two are connected to form a whole by means of Hog Ring or Velcro. This coating scheme has a relatively large workload, and the coating operation tolerance is difficult to control. The skin may wrinkle, affecting the appearance. With the development and improvement of automobile seat foaming technology, the PIP method has entered the seat design and manufacturing link. The mold is fixed to the cover, and the pouring and curing are completed at one time, which can effectively avoid the wrinkle problem. However, the PIP method also has certain limitations. It is difficult to fix the mold, which may lead to an increase in the scrap rate. Therefore, at this stage, many automobile manufacturers have begun to decompose the entire structural layer of the seat from top to bottom and analyze the foaming materials in the structural layer. The foaming layer is located within the leather composite layer, which can better solve the wrinkle problem on the seat surface, reduce the scrap rate, and improve the comfort and aesthetics of seat manufacturing.

1.2 Comfortable foaming Comfortable foaming is a manufacturing process that fits the foaming surface of the seat. Audi's cut foam is a representative type of this process. Its seats use a multi-layer foaming method, and the hysteresis loss rate close to the surface layer is low. Different characteristics are related to different perception directions of comfort. During operation, it is necessary to mix polyurethane and foaming agent according to the ratio, and add a certain amount of catalyst and stabilizer to make the mixture react and expand quickly and fit the inner wall of the mold. The main component of the seat filling layer obtained under this process is polyurethane foam sponge, which has a relatively high-quality pore structure, low density, light texture, and ideal softness and elasticity. It can achieve shock absorption and buffering effects and conform to ergonomic principles. Therefore, it is also called "memory sponge layer". In addition, the durability and wear resistance of this material attached to the foam surface of the seat are also relatively outstanding. Even in a long service life, it can ensure a good user experience, improve riding comfort while extending the service life, and delay the deformation and aging speed of the car seat.

1.3 Foaming body According to different foaming reaction conditions, the foaming body can be subdivided into hot foaming and cold foaming. Among them, hot foaming is more commonly used in the European automobile manufacturing industry. During operation, the mixture needs to be poured into the mold and cured at 220~250℃ to form a flexible cured foaming structure. After demoulding, the surface layer is well connected to make a finished seat that can be used. The seat made of hot foaming has good heat resistance and a slow aging speed in a high temperature environment, but the energy consumption is relatively large. Cold foaming is a common method in my country's automobile manufacturing process, and the existing production line system is relatively complete. When applied, the mold needs to be heated first, and then the PU mixture is poured for demoulding. Compared with hot foaming technology, this technology has a relatively low energy consumption level and more considerable economic benefits, but the production line needs to add mold temperature controllers, bubble breakers, etc., and the equipment system is relatively complex.

2 The relationship between the collapse of automobile seats and foaming performance

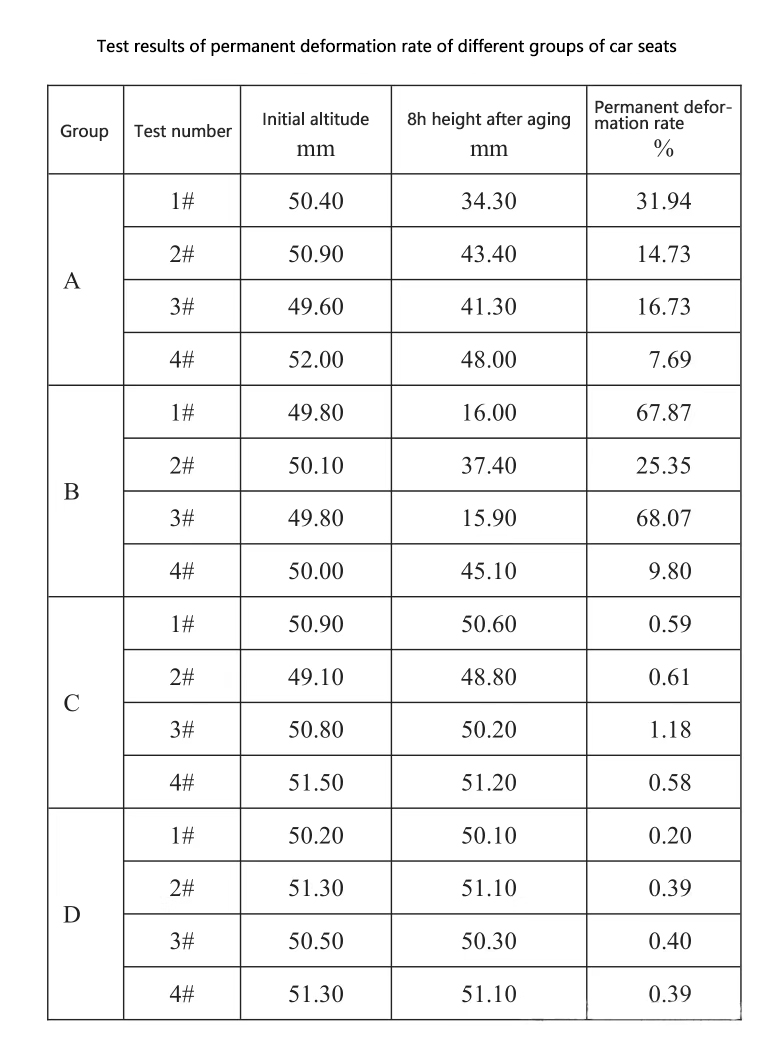

2.1 The permanent deformation rate under different foaming performances In order to verify the relationship between the collapse degree of automobile seats and foaming performance, a special research test was designed. In the permanent deformation rate test, four groups were mainly set up to simulate different working environments of automobile seats. Group A simulates a hot and humid environment, with a test temperature of 50 ℃ and a humidity of 95%; Group B simulates a dry and hot environment, with a test temperature of 70 ℃ and a humidity of 50%; Group C simulates a normal temperature environment, with a test temperature of 23 ℃ and a humidity of 50%; Group D simulates a low temperature environment, with a test temperature of -30 ℃ and a humidity of 50%. The samples are numbered from 1# to 4#, where 1# uses low-hardness foaming, and the density of the foaming material is controlled at 45 kg/m 3; 2# uses high-hardness foaming, and the density is also 45 kg/m 3; 3# uses low-hardness foaming, and the density is controlled at 70 kg/m 3; 4# uses high-hardness foaming, and the density is 70 kg/m 3. The dimensions of the four groups of samples are 100 cm×100 cm×50 cm, and the height of the samples is measured uniformly before the test. Then the samples are compressed to 75% and placed in different temperature and humidity environments for testing. After 24 hours of storage, they are taken out, the height is re-measured, and the permanent deformation rate is calculated. The calculation method is (initial height-height after deformation)/initial thickness×100%. The specific test results are shown in Table 1.

From the test results, the average permanent deformation rate of the seats in Group D is the lowest among the four groups, indicating that the deformation and aging speed of the seats is relatively slow in low temperature environments, while the average permanent deformation rate of the foam material in Group B's dry heat environment is the highest. This may be because the high temperature environment destroys the original stable structure of the foam material, causing the water in it to be lost, reducing the material's resilience, and causing the permanent deformation rate to increase. From the perspective of material manufacturing technology, in the wet and hot environment of Group A, the 1# low-hardness, low-density foaming method has the highest permanent deformation rate, and the 4# high-hardness, high-density foaming method has the lowest permanent deformation rate. Analysis found that this may be because the internal structure of the 1# material is looser under the same size, and its own resilience after compression is weaker. Coupled with the influence of the wet and hot environment, the curing ability of the sample is insufficient, and some materials even stick together, resulting in an increase in the permanent deformation rate. In the dry heat environment of group B, the permanent deformation rates of samples 1# and 3# are relatively high, both exceeding 65%, while the permanent deformation rate of sample 4# is the lowest, because the internal structure of the material is more compact under the high hardness and high density foaming method, the internal rebound expansion stress is higher after compression, and the height loss will be reduced accordingly, followed by the 2# high hardness foaming method. Although its density is low, the addition of foaming agents, catalysts, etc. will increase the adhesion and connection between microscopic molecules, and enhance its ability to resist loads and prevent deformation. The permanent deformation rates of samples 1# to 4# in groups C and D are basically maintained at around 1%, and the overall difference is not large. These test data show that under high temperature (50 ℃+) and high humidity (70+) environments, the permanent deformation rate of long-term compressed foaming will increase, and the seat will collapse, while under low temperature and room temperature environments, the permanent deformation of the seat is relatively small. In addition, high hardness and high density have a certain optimization effect on foam deformation after wet heat; other parameters are not strongly correlated with foam collapse after durability. When the foaming process is applied to automobile seats, the foaming hardness and density can be appropriately increased to optimize durability. Considering that high-hardness foaming may damage comfort, the process plan can also be optimized and adjusted, using low-hardness foaming in the seating area and high-hardness foaming in the support area, setting a material separation groove in the middle, adding embedded parts, etc., while reducing the permanent deformation rate, improving the durability of the seat.

2.2 Test results of seat cushions and backrest springs under different foaming conditions

In addition to the permanent deformation rate test, this study also conducted performance tests on seat cushions and backrest springs. The main test instruments are seat static load testers, laser marking instruments, rotating platforms, and angle meters. The main test materials are Φ50 mm indenters and seat cushion samples with a size of 250 mm×350 mm×5 mm. The samples use 4 different foaming methods, and the specific parameters are the same as 2.1. The main purpose of the test is to simulate the human body's sitting position and load action scenarios, and objectively evaluate the deformation performance of seat cushions and backrests under different foaming conditions. To achieve this goal, the load application point and data measurement point must be accurately calculated and marked before the test begins to provide support for subsequent measurement operations.

First, fix the seat frame on the positioning fixture, and refer to the design plan to adjust the seat to a suitable reference state. The test data is mainly collected by the laser line marker, so the instrument cross cursor should be aligned with the center of the seat REC test to facilitate the instrument to identify the target and collect data. Then, according to the human body's riding habits, find the intersection of the torso line and the thigh line, that is, the H.P point, readjust the state of the laser line marker, and align it with the H.P point by shaking the handle. With the help of the laser line marker, project the red line, find the intersection between the red line and the center axis of the seat, mark it as point b, and move it up 35 mm to mark point a. Fix the seat on the rotating platform and adjust the seat angle based on point b until point b is in a horizontal state.

After the adjustment preparation is completed, the simulation test can be carried out. Adjust the static load tester pressure head to ensure that its center point is aligned with the marked pressure point a, then place the sample to be tested, adjust the static load parameter value to 350 N, and control the loading speed to 200 mm/min for testing. To ensure that the test instrument is in good operating condition, the initial load parameter of 5 N can be used for pre-pressing during operation. No data needs to be recorded during the period. After unloading, formal test is carried out and relevant test results are recorded. After completion, change the load to 200 N and record the deflection at points a and b. When testing the backrest, the seat fixing adjustment method is the same, but it is necessary to use the H.P point as the center, vertically paste the masking tape along the Torsoline direction, and mark multiple measurement points at intervals of 50 mm to complete the data collection.

The results show that the collapse of the 4# cushion is the slightest, followed by the 2# cushion, and the 1# and 3# cushions are the most serious. The collapse depth is 2~3mm, and the collapse amount at the center of the test point is the largest and gradually decreases outward. In the backrest spring test, the foaming structure of the 1# backrest was damaged and some springs were exposed. This may be because the internal structure support capacity is insufficient under the low-density and low-hardness foaming method. The structure was damaged during compression, resulting in exposure. The hardness of the 3# sample is relatively small and the deformation is relatively large, but due to sufficient density, there is no spring exposure. The 4# backrest collapsed the least, but excessive hardness may reduce comfort. The 2# backrest has high hardness but relatively low density, and only a slight collapse occurred.

3 Methods for preventing automobile seat collapse and foaming performance optimization methods

3.1 Methods for preventing seat collapse From the above analysis, it can be found that the application of high-hardness foaming can improve the performance of automobile seat materials to a certain extent, reduce its permanent deformation rate, and extend the service life of seats, backrests, etc. However, excessive hardness of foaming materials will lead to reduced riding comfort. Therefore, while improving the foaming technology, it is also necessary to explore practical and feasible methods for preventing seat collapse. Research can be carried out from the following two aspects.

(1) Seat spring optimization design. The main reason for the collapse of the seat cushion is fatigue and bumping. During the bumpy driving of the vehicle, the impact force generated can reach more than 3 times the body weight of the human body. This can be used as a reference value when designing the spring to optimize the selection of spring materials and adjust the diameter of the spring wire to ensure that the spring can withstand a load of more than 2,250 N (assuming the weight of the passenger is 75 kg).

(2) Optimization design of the seat wire structure. The unreasonable connection between the wire structure and the frame is also an important reason for the collapse of the seat. After the connection part slips, the seat loses support locally, which can easily lead to collapse. Therefore, when designing and manufacturing, it is necessary to reasonably select the material and length of the connection material to improve the fixing performance of the wire structure and reduce the risk of seat collapse.

3.2 Foaming formula/performance optimization The foaming formula will also affect the performance and durability of the car seat. Therefore, the anti-collapse design also needs to actively optimize the formula and raw materials to promote the improvement of foaming performance. The common foaming raw materials are mainly polyurethanes, among which the polyols have strong flexibility and can improve the rebound rate of the foaming material. The specific types include polyether polyols, polyester polyols, etc. Isocyanate is the key component involved in the foaming reaction. The options include TDI and MDI. The types and proportions should be adjusted according to the actual situation. At the same time, the chain extenders used in different polyurethane raw materials are also different. This substance can effectively extend the length of the molecular chain and improve the uniformity and stability of the foam. The optional types include ethylene glycol, propylene glycol, etc.

Foaming agents and catalysts will also directly participate in the foaming of car seats, which can promote the expansion of raw materials and shorten the foaming time. In the actual design and manufacturing process of car seats, it is necessary to scientifically grasp the properties and characteristics of different components, determine the best ratio through the design of parallel tests and comparative tests, ensure the improvement of car seat comfort and safety, and ensure the extension of seat service life.

4 Conclusion

The foaming process directly affects the user experience of car passengers, and it must be given full attention in practice. Automobile companies should deeply study and grasp the characteristics, advantages and disadvantages of different foaming technologies, and choose appropriate types of foaming processes in combination with automobile brand positioning, audience needs and economic costs. Experiments show that there is a correlation between the collapse of car seats and foaming performance. Therefore, we should understand the permanent deformation rate of the seat, the performance of the seat cushion and backrest springs under different foaming conditions, and design the seat springs and seat wire structure on the premise of fully mastering the quantitative data. We should scientifically adjust the foaming formula and proportion to lay a solid foundation for improving the quality of car seats.

+86 19906048932

+86 19906048932 sales@luxuryvanseat.com

sales@luxuryvanseat.com | Blog

| Sitemap

| XML

| Privacy Policy

| Blog

| Sitemap

| XML

| Privacy Policy