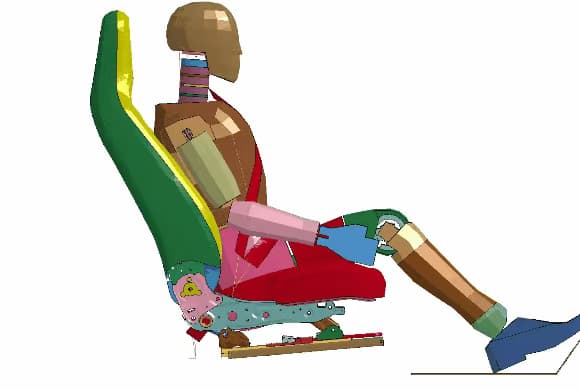

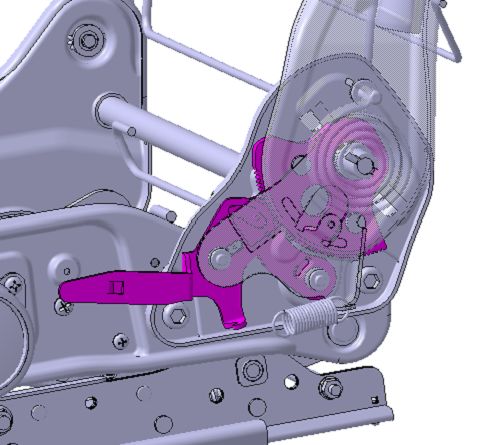

An angle adjuster is a load-bearing device installed between the seat back and seat pan, mainly used to achieve the tilt angle and folding movement of the seat back, adapt to different human posture requirements, and serve as a transmission structure for the force exerted by the human body on the backrest.

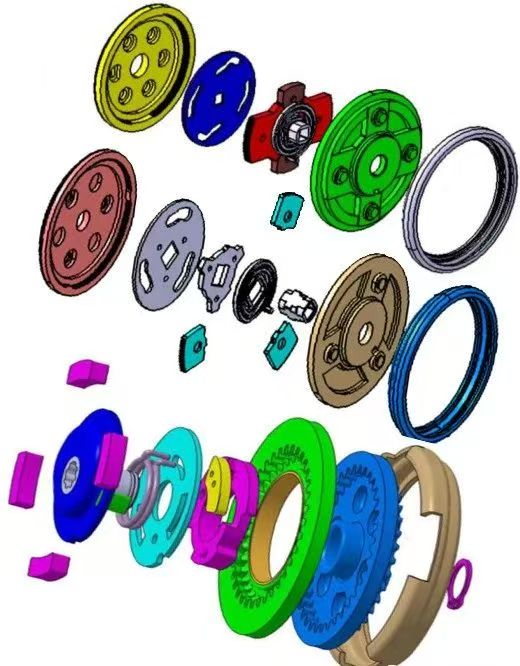

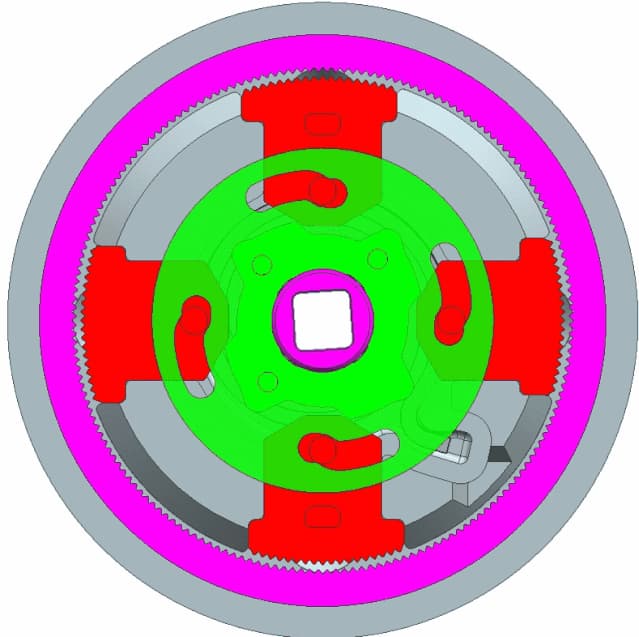

Angle adjusters generally consist of upper and lower connecting plates (some called AB plates), core components, connecting rods, handwheels or adjustment handles, return springs, and other parts.

The core technology of the angle adjuster lies in the parameter design and manufacturing of the tooth profile, and there is no directly replicable program in tooth profile design. Because the internal and external teeth are the main force bearing parts, there are high requirements for the tooth profile, tooth surface quality (tooth surface roughness, wear resistance, fatigue strength), and tooth root strength.

The core of tooth profile design is the smooth meshing of the tooth surface and the high number of contact teeth at any position, with the ultimate goal of improving transmission efficiency and maximizing tooth profile strength. Therefore, angle adjusters use precision stamping technology.

The main function of the angle adjuster is:

1. Adjust the backrest angle of the seat to meet different seating posture requirements and improve comfort;

2. To bear/transmit torque loads, ensure the strength and stiffness of the seat/back connection, and increase protection for passengers during collisions;

Classification of angle adjusters:

Divided by driving mode:

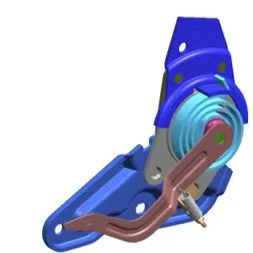

① Manual angle adjuster: an angle adjuster that can be adjusted by turning the handle or rotating the handwheel to adjust the backrest.

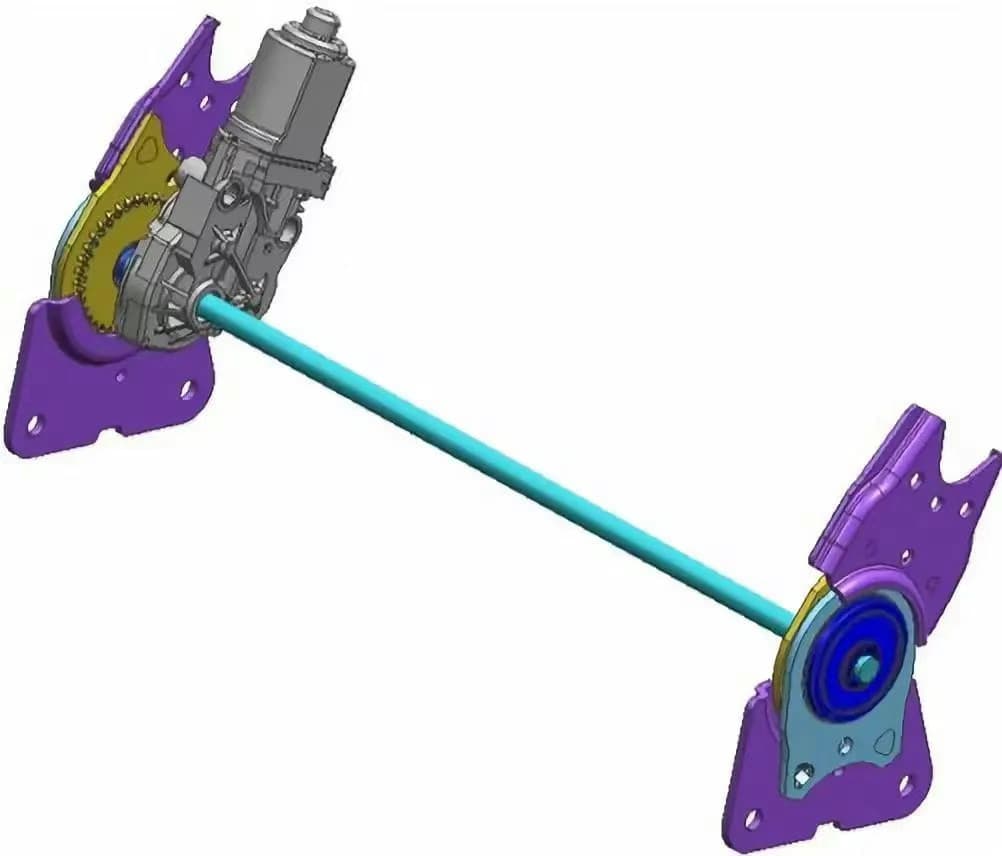

② Electric angle adjuster: an angle adjuster that adjusts the backrest angle through motor control.

Classified by usage environment:

① Unilateral angle adjuster: Only one side of the backrest side panel and seat cushion side panel is connected with an angle adjuster. The advantage of this structure is that it is relatively inexpensive, but the stiffness and strength of the backrest are slightly lower.

② Bilateral angle adjuster: There are angle adjusters on both sides of the backrest side panel and seat cushion side panel, connected by a connecting rod. The advantage of this structure is that the use of symmetrical and shared components can reduce the number of parts, and the stiffness and strength of the backrest are relatively high, but the cost is slightly higher.

Divided by meshing method:

① Continuous angle adjuster: an angle adjuster with stepless adjustment of the backrest angle, which has the advantage that the backrest can be adjusted to any angle position within the adjustment range.

② Non continuous angle adjuster: an angle adjuster with adjustable backrest angle, usually with a 2deg adjustment stroke per gear.

Common angle adjusters:

Below 1500Nm level: mostly used in some models with lower requirements;

1800Nm level: the most widely used angle adjuster;

3500Nm level: When the fixing point on the seat belt is on the seat, or when the second row 4/6 folding independent seats are more commonly used.

+86 19906048932

+86 19906048932 sales@luxuryvanseat.com

sales@luxuryvanseat.com | Blog

| Sitemap

| XML

| Privacy Policy

| Blog

| Sitemap

| XML

| Privacy Policy